Single / Double Side Vacuum Forming LED Light Box 110V-220V For Bank

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Single/Double Side 110V-220V Vacuum Forming Outdoor Lig

Single/Double Side 110V-220V Vacuum Forming Outdoor Light Box for Bank

Production Information

1. Main support:

flectional aluminum extrusion:

Aluminum frame width:6cm / 8cm / 10cm / 11.5cm option, different color finishing is acceptable, metal feet support, mounting on the wall or hanging on the ceiling.

2. Image media:

Opal acrylic with silk screen printing logo or blank acrylic surface with changeable inkjet Self-adhesive backlit vinyl film poster.

3. Electricity:

energy saving fluorescent tube, electronic ballast, CE and UL approval is available.

4. Packing:

bubble bag for individual ,foam corner protection ,wooden case/carton packing is available

Technology: thermoform, mould sucking

Product Details

| Product | Single side 110V-240V vacuum forming outdoor light box for Bank |

| Material | Aluminum frame, import acrylic board, ballast |

| Durable | outdoor used; wall mounted |

| Printing | 1 color or 4 color silk screen printing |

| Characteristic | 1. Vacuum moulding |

| 2. custom shape available | |

| 3. Frame colors: silver | |

| 4. Voltage: 110V-240V | |

| Size | 5. Customized is available |

| Light set | long life span lights and electronic ballast |

| Certification | CE, ROSH, UL, SASO |

| Application | Bank image sign, reception, ATM, chain store, bar, shopping mall, hotel, restaurant, exhibition hall, etc. |

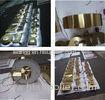

Vacuum forming progress

Step1. Make the plastic sheet be clamped into position which above the

vacuum forming mold inside the vacuum forming machine.

Step 2

The sheet is then heated by two heaters one above the sheet and one below the sheet.

This method is called sandwich heating and gives a more consistent temperature

throughout the sheet avoiding any cold areas which in turn gives you a sharper and

more defined vacuum forming .

Step 3

Once the sheet is heated to the correct temperature it will become pliable, the

vacuum forming mold is raised and a vacuum is applied which pulls the now

malleable plastic sheet down onto the vacuum forming mold.

Step 4

The vacuum is kept on while the plastic is cooled using large fans and water spray so

that it retains the shape off the vacuum forming mold.

Step 5

Once the plastic is cooled the vacuum is released and the plastic part removed by

gently applying a short blast of air between the vacuum forming mold and the plastic

component.

Step 6

Pick the plastic sheet which is finished vacuum forming out from the vacuum forming

machine.

Step 7

Cut the edge by CNC machine or hand.

Step 8

Cleaning and packing.

Progress as is shown in:

Specifications:

| Product Name: | Vacuum forming light box | Brand: | Weldon |

| Product Application: | Bank | Material: | Aluminum, acrylic |

| Size: | customized | Features: | Display any logos |

| Light Source: | LED module/tube option | Frequency: | 50-60HZ |

| Printing: | Anti-UV/silk screen | Light Distance: | 0-5m |

| Light set: | long life span lights and electronic ballast | Frame colors: | Silver |

| Voltage: | 110V-240V | Shape: | Rectangle, round, square, etc. |

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Weldon Industrial Limited Company [China (Mainland)]

Business Type:Manufacturer

City: Guangzhou

Province/State: Guangdong

Country/Region: China (Mainland)